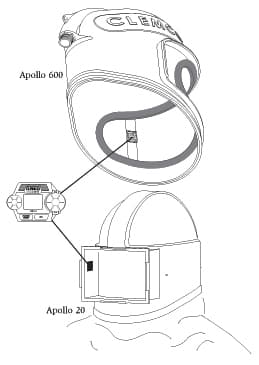

In-Helmet Carbon Monoxide Monitor

The small CO sensor goes inside your air-fed helmet to monitor CO levels for your protection. Comes with canister and tubing to test/calibrate it weekly.

Respirator-Mounted Clemco 24613 CMS-3 CO Monitor

AA1329 CLEMCO CO MONITOR FOR HELMET

CMS-3 Carbon Monoxide Monitor/Alarm

The CMS-3 monitor detects carbon monoxide in the breathing-air supply and triggers audible, visual, and vibratory alarms when CO is detected in concentrations of at least 10 parts per million. The alarms alert the operator to an unsafe condition.

Requirements for Operation

Battery installed in the CMS-3

25 ppm calibration gas, calibration cup and connector

Grade D or ambient-air breathing-air supply for the abrasive blast operator

Thorough familiarity with the CMS-3 instructions

Description of Operation

OSHA requires Grade D quality breathing air and NIOSH-approved Type CE continuous-flow supplied-air respirators for abrasive blast operators. OSHA regulations call for a maximum exposure limit to carbon monoxide of 10 parts per million (ppm). When the presence of carbon monoxide is detected at this level, the CMS-3 emits an audible alarm, a visible flash, and the unit vibrates. When an alarm occurs, the user should remove the respirator immediately when it is safe to do so. To prolong battery life, turn unit off when not in use; turn unit on and re-install at beginning of work shift.

CMS-3 Features

Digital liquid crystal display (LCD)

Audible, visual, and vibrating alarms

Low battery alarm

Sensor fail alarm

Replaceable sensor and battery

Advantages

Blast operator can work independently. No need to rely upon others to warn operator or take action when monitor alarms. No need for remote alarm; each user is individually protected for instant awareness of a hazardous condition.

- Unit is small, lightweight, and conveniently worn inside blast respirator. Requires no external connections or hoses.

- Unit can be calibrated in minutes, is easily installed, and easily removed.

- Long-life, economical easy-to-replace sensor with estimated sensor life of 2 years.

- Unit uses small commonly-available lithium easy-to-replace battery with estimated life of 3000 hours.

- Microprocessor controlled with digital read-out for accurate readings.

Specifications

OSHA rules dictate that maximum exposure limit to CO for abrasive blasters breathing Grade D air is 10 parts per million.

- Sampling by diffusion

- Operating temperature and humidity range: -4 to 104 degrees F (-20 to 40 degrees C); up to 85 percent relative humidity (non-condensing) factory set at 10 ppm

- Accuracy rating: plus or minus 2 ppm

- Powered by 3-volt coin-type lithium battery (CR2450)

- Continuous operation: approximately 1 year of normal use (3000 hours)

- Unit net weight 1.6 ounces (0.1 lb)

- Dimensions: 2.5″ w x 1.7″ h x 0.9″ d

- Unit calibrated with 25 ppm test gas; optional impurity-free gas available for fresh-air setting audible, vibratory, and visual alarms

- Low-battery warning given by visual flashing indicator

- Dead battery indicated by audible alarm

- System failure warning given by audible alarm

- Attachment to respirator: VELCRO®

- Warranty: 2 years material and workmanship

Available Literature:

CMS-3 Technical Data Sheet

Operation Manual: CMS-3 In-Helmet Carbon Monoxide Monitor

| part-no | |||

|---|---|---|---|

| AA1329 | CO MONITOR FOR HELMET | ||